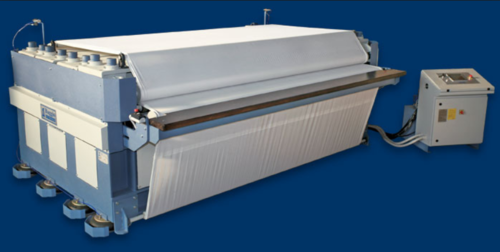

क्लॉथ या लेथर स्टेकिंग मशीन में पीएलसी प्रोग्रामिंग और ऑटोमेशन

उत्पाद विवरण:

X

क्लॉथ या लेथर स्टेकिंग मशीन में पीएलसी प्रोग्रामिंग और ऑटोमेशन मूल्य और मात्रा

- 1

- यूनिट/यूनिट

- आईएनआर

क्लॉथ या लेथर स्टेकिंग मशीन में पीएलसी प्रोग्रामिंग और ऑटोमेशन व्यापार सूचना

- कैश इन एडवांस (CID), चेक, कैश एडवांस (CA)

- 50 प्रति महीने

- 2-6 हफ़्ता

- ऑल इंडिया

उत्पाद वर्णन

Experience exceptional efficiency with our PLC Programming and Automation system, designed exclusively for Cloth and Leather Staking Machines. Unlock instant savings with our peerless offering, featuring integrated pressure, position, and temperature sensors. Enjoy the lowest priceorder today and benefit from advanced safety elements like emergency stop, overload protection, and interlocking. The imposing system supports programmable cycle time, data logging with trend analysis, and remote monitoring via Ethernet. Maintenance alerts and smart diagnostics maximize uptime. This solution is the optimum choice for manufacturers, dealers, exporters, and more across India seeking robust, high-precision automation.

Extraordinary Features and Material Benefits

Our cutting-edge PLC programming for cloth and leather staking machines delivers exceptional automation and safety. Integrated sensors monitor pressure, position, and temperature for peerless process control. Users benefit from advanced data logging for historical analysis, automatic maintenance alerts, and versatile cycle time adjustments. This solution is used across industries as a reliable, efficient tool for maximizing throughput, with both manual and automatic modes, making it adaptable for different material processing environments.

Markets, Supply, and Shipment Details

Proposals for exports and domestic supplies are available with highly competitive expenditure options. Our main export markets span Southeast Asia, Africa, and the Middle East, while our domestic market focuses on key industrial zones across India. With a robust supply ability and streamlined shipment procedures, clients can expect prompt delivery in line with the proposal amount. Our refined logistics ensure on-time and safe delivery tailored to dealers, traders, and other business partners.

Extraordinary Features and Material Benefits

Our cutting-edge PLC programming for cloth and leather staking machines delivers exceptional automation and safety. Integrated sensors monitor pressure, position, and temperature for peerless process control. Users benefit from advanced data logging for historical analysis, automatic maintenance alerts, and versatile cycle time adjustments. This solution is used across industries as a reliable, efficient tool for maximizing throughput, with both manual and automatic modes, making it adaptable for different material processing environments.

Markets, Supply, and Shipment Details

Proposals for exports and domestic supplies are available with highly competitive expenditure options. Our main export markets span Southeast Asia, Africa, and the Middle East, while our domestic market focuses on key industrial zones across India. With a robust supply ability and streamlined shipment procedures, clients can expect prompt delivery in line with the proposal amount. Our refined logistics ensure on-time and safe delivery tailored to dealers, traders, and other business partners.

FAQs of PLC Programming And Automation in cloth or lather staking Machine:

Q: How does the PLC automation system improve staking machine performance?

A: The PLC-driven system provides real-time control over staking operations, optimizes cycle times, supports data analysis, and enhances safety through advanced features like emergency stops and overload protection, resulting in improved productivity and reduced downtime.Q: What materials can be processed with this machine?

A: The system is engineered for both cloth and leather staking operations, ensuring precise and efficient material processing with reliable quality and repeatability.Q: When should maintenance be scheduled for the machine?

A: Maintenance schedules are automated and managed by the system diagnostics, providing timely alerts on the HMI, ensuring proactive care and minimizing unexpected breakdowns.Q: Where can the machine be monitored remotely?

A: Remote monitoring is supported through an Ethernet interface, allowing authorized users to track operational data and trends from anywhere with network access for seamless productivity oversight.Q: What are the major safety features integrated into the machine?

A: Safety is ensured with emergency stop controls, overload protection, interlocking mechanisms, user authentication, and an IP54-rated enclosure for robust and secure operation in industrial environments.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

परियोजनाएँ एवं सेवाएँ अन्य उत्पाद

|

ECOSYS EFFICIENCIES PVT. LTD.

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें