PLC, HMI & Servo Programming and Automation in Labelling machine

Product Details:

X

PLC, HMI & Servo Programming and Automation in Labelling machine Price And Quantity

- 1 Unit

- INR

PLC, HMI & Servo Programming and Automation in Labelling machine Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 50 Unit Per Month

- 2-6 Week

- Australia, South America, Western Europe, Middle East, Central America, Africa, Asia, Eastern Europe, North America

- All India

Product Description

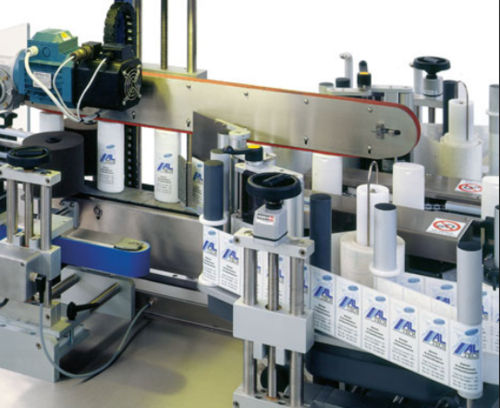

Labelling machines are machines that dispense, apply or print-and-apply labels to various items, products, containers, or packages. Our team Ecosys Efficiencies PVT. LTD. has huge experience in this kind of machine (Servo drive application), For high-speed production output with 100% Accuracy.

Precision Control for Labeling Applications

Achieve pinpoint accuracy with synchronized servo-driven labeling, utilizing advanced encoder-based speed control for label placement. The PLC enables rapid automation cycles, while the touchscreen HMI ensures seamless machine operation and monitoring.

Comprehensive Safety and Reliability

The labeling solution integrates essential safety measures including emergency stop, overload protection, and audible alarms. Its built-in diagnostics and error code logging ensure quick troubleshooting, maintaining consistent operation in a protected control environment.

Scalable and Connected for Modern Production

Easily expand your systems I/O to fit evolving production demands. Remote connectivity via Ethernet/IP or IoT gateway, plus multi-level HMI access and firmware upgrades, allow for centralized management and secure, future-ready automation.

FAQs of PLC, HMI & Servo Programming and Automation in Labelling machine:

Q: How does the labeling machine ensure precise label placement and reliable operation?

A: The machine uses encoder-based conveyor speed synchronization combined with servo motor control, ensuring accurate label positioning on each product. Absolute or incremental encoders provide real-time feedback, maintaining precision even at speeds up to 300 bottles per minute.Q: What safety features are integrated into the automation system for labeling machines?

A: The system includes emergency stop functionality, fault alarms, overload protection, and alarm indications both on-screen and via an audible buzzer, making sure operators and equipment are safeguarded during operation.Q: When should I consider using modular I/O expansion for my labeling automation system?

A: Modular I/O expansion is recommended when your labeling process requires additional input or output points, such as for integrating sensors, actuators, or new automation tasks as your production needs grow.Q: What are the remote access and data logging capabilities of the system?

A: The labeling system offers optional Ethernet/IP or Industrial IoT gateway connectivity for remote diagnostics and firmware upgrades. Built-in data logging tracks labeling cycles and error codes, supporting efficient maintenance and troubleshooting.Q: Where is the ideal mounting location for the control components in this labeling solution?

A: Control elements including the PLC and HMI are designed for panel or DIN rail mounting within an enclosed control panel. This setup secures the wiring channels, safety relays, and protects components in industrial environments.Q: How does recipe management in the HMI benefit multi-product labeling operations?

A: Multi-product recipe management allows operators to store, select, and quickly switch between different labeling parameters in the HMIs memory. This greatly increases efficiency and reduces downtime during product changeovers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Projects & Services' category

|

ECOSYS EFFICIENCIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free