PLC Programming and Automation

Product Details:

X

PLC Programming and Automation Price And Quantity

- INR

- 1 Unit

PLC Programming and Automation Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 50 Unit Per Week

- 2-6 Week

- South America, Middle East, Central America, Western Europe, Asia, Eastern Europe, North America, Australia, Africa

- All India

Product Description

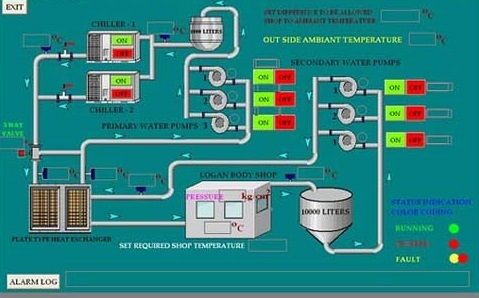

Experience a rare blend of elite technology and illustrious reliability with this matchless PLC Programming and Automation solution, tailor-made for demanding industrial environments. With bargain pricing and robust features, pick yours to unlock seamless process control and automation. Supporting Ladder Logic, Function Block Diagram, Structured Text, and Instruction List, it offers maximum flexibility. Communication is effortless via Ethernet, RS232, RS485, and USB ports. With multiple I/O expansion, temperature resilience (0C to 60C), rapid cycle time (<1 ms), and versatile indicators, it stands unmatched in its class for automation dealers, exporters, and retailers across India.

Material & Special Features for Reliable Industrial Automation

These PLC Programming and Automation systems are constructed with premium-grade components, ensuring durability in rigorous industrial settings. Special features include multi-language supportLadder Logic, Function Block Diagram, Structured Text, and Instruction Listcatering to versatile automation demands. Designed for both digital and analog inputs/outputs, the products shine in sectors like industrial automation, process control, and machine automation. Expansion capability for multiple I/O modules enables scalability, while LCD or LED indicators provide user-friendly system monitoring.

Reliable Supply, Flexible Payments, and Global Delivery

Our firm delivers these PLC units reliably across India and to main export markets worldwide. We offer tailored transport services to ensure every product arrives safely at your facility. With consistent supply ability, we cater to dealers, exporters, and wholesalers, supporting large-scale industrial projects. Flexible payment terms are available to simplify procurement. Through partnerships with premier logistics providers, clients benefit from punctual deliveries, secure handling, and professional support throughout the process.

Material & Special Features for Reliable Industrial Automation

These PLC Programming and Automation systems are constructed with premium-grade components, ensuring durability in rigorous industrial settings. Special features include multi-language supportLadder Logic, Function Block Diagram, Structured Text, and Instruction Listcatering to versatile automation demands. Designed for both digital and analog inputs/outputs, the products shine in sectors like industrial automation, process control, and machine automation. Expansion capability for multiple I/O modules enables scalability, while LCD or LED indicators provide user-friendly system monitoring.

Reliable Supply, Flexible Payments, and Global Delivery

Our firm delivers these PLC units reliably across India and to main export markets worldwide. We offer tailored transport services to ensure every product arrives safely at your facility. With consistent supply ability, we cater to dealers, exporters, and wholesalers, supporting large-scale industrial projects. Flexible payment terms are available to simplify procurement. Through partnerships with premier logistics providers, clients benefit from punctual deliveries, secure handling, and professional support throughout the process.

FAQs of PLC Programming and Automation:

Q: How do these PLC systems support various programming languages for automation?

A: These PLCs are engineered to accommodate multiple programming languages, including Ladder Logic, Function Block Diagram, Structured Text, and Instruction List, allowing automation engineers to select the most suitable approach for their application.Q: What are the main industrial applications for these PLC Programming and Automation units?

A: They excel in industrial automation, process control, and machine automation, effectively handling both digital and analog inputs/outputs to streamline operations in manufacturing plants, factories, and automation setups.Q: Where can these PLC solutions be installed and mounted?

A: Designed for flexibility, these PLC units can be mounted using either DIN rail or panel mount methods, ensuring compatibility with diverse cabinet or enclosure configurations in industrial settings.Q: What advantages do the multiple communication ports offer?

A: With Ethernet, RS232, RS485, and USB connectivity, these PLCs provide versatile communication options for integration with existing industrial networks, enabling seamless data exchange and remote monitoring.Q: When is expansion of I/O modules recommended during installation?

A: Expansion of I/O modules is recommended when your automation requirements exceed the built-in I/O capacity, enabling scalable configurations that evolve with growing or changing application needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Projects & Services' category

|

ECOSYS EFFICIENCIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS