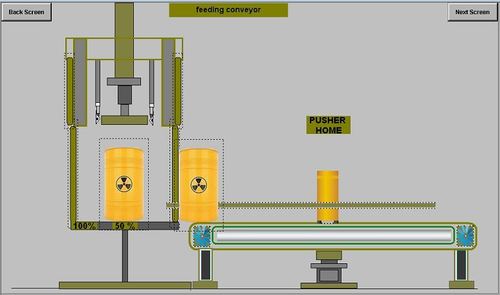

PLC Programming in Waste Disposal And Compaction Machine

Product Details:

X

PLC Programming in Waste Disposal And Compaction Machine Price And Quantity

- 1 Unit

- INR

PLC Programming in Waste Disposal And Compaction Machine Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 50 Unit Per Month

- 2-6 Week

- All India

Product Description

Waste compaction is the process of compacting waste, reducing it in size. Garbage compactors and waste collection vehicles compress waste so that more of it can be stored in the same space

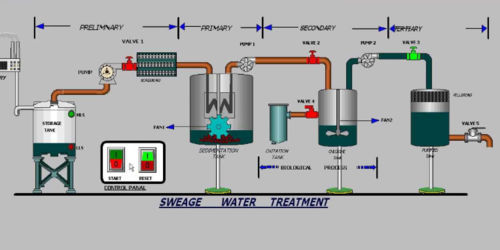

Comprehensive Expansion and Connectivity

The system supports a wide range of expansion modules, enabling I/O, remote communication, and additional network connectivity. With compatibility for Ethernet, Modbus, and Profibus, the PLC can be easily integrated into both new and existing environments. This enables remote monitoring, data logging, and control from web servers and SCADA systems, enhancing management efficiency.

Flexible Operation and Safety Features

Waste compaction cycles are programmable via HMI panels, supporting both automatic and manual operation modes. Integrated safety interlocks such as emergency stop, door limit switches, and overload protection ensure user and equipment safety. This allows operators to adjust cycle times, monitor status, and respond promptly to maintenance needs.

Versatile Installation and Robust Design

Designed for industrial use, the PLC and its modules can operate between -10C to +55C and feature DIN rail or panel mount options. With IP20 to IP54 ratings depending on installation, they offer protection against dust and moisture. Expandable memory and reliable power supply options provide long-term performance for various waste compacting setups.

FAQs of PLC Programming in Waste Disposal And Compaction Machine:

Q: How can I expand the I/O capacity or add communication protocols in my waste compaction machine?

A: Expansion modules for I/O and communication can be added as needed, enabling support for additional sensors, actuators, or protocols such as Ethernet, Modbus, and Profibus. This customizable approach allows the system to grow alongside operational requirements.Q: What programming languages are supported for configuring the PLC?

A: You can program the PLC using Ladder Logic, Structured Text, and Functional Block Diagrams. This versatility accommodates various application complexities and engineering preferences, ensuring tailored process control.Q: When should the cycle time be adjusted, and how is it done?

A: Adjust cycle times via the HMI touchscreen or panel during setup or whenever process demands change, such as varying waste volumes. Cycle parameters are fully programmable to match operational workflows and optimize compaction efficiency.Q: Where is the system typically mounted, and what IP rating is available?

A: The PLC can be mounted on DIN rails or panels, depending on installation needs. Depending on the chosen mounting and accessories, the system offers IP20 to IP54 ratingsensuring protection in dust-prone or moderately wet environments.Q: What safety interlocks are included and how do they benefit operation?

A: Integrated safety features such as emergency stop buttons, door limit switches, and overload protection safeguard users and prevent equipment damage, promoting reliable and secure waste management operations.Q: How does data logging and remote monitoring work with this system?

A: The PLC features real-time data acquisition and logging to on-board expandable flash memory. SCADA compatibility and optional web server access allow remote monitoring, diagnostics, and performance evaluation, thereby improving operational oversight and maintenance planning.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Projects & Services' category

|

ECOSYS EFFICIENCIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS