PLC Programming For Heat Stacking Machine

Product Details:

X

PLC Programming For Heat Stacking Machine Price And Quantity

- INR

- 1 Unit

PLC Programming For Heat Stacking Machine Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 50 Unit Per Month

- 2-6 Week

- Africa

- All India

Product Description

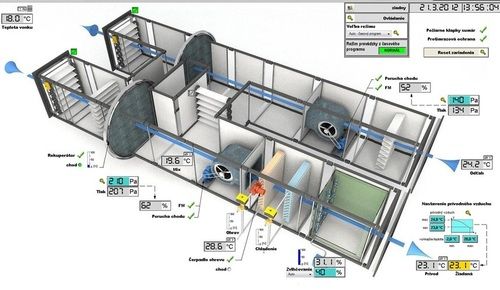

Unlock an imposing level of automation with our PLC Programming for Heat Stacking Machines. Now available at a discounted, bargain price, this praiseworthy solution features seamless communication via Modbus, Profibus, and Ethernet/IP. Benefit from opulent temperature control accuracy of 1C and versatile I/O connectivity for both digital and analog signals. Our program supports Siemens, Allen-Bradley, Mitsubishi, and Omron brands, integrating smoothly with HMIs. Panel mounting, CE certification, remote upgrades, and comprehensive customization ensure superior reliabilityideal for dealers, exporters, and fabricators across India. Dont miss this reduced-price offer on a truly efficacious control system.

Broad Applications and Competitive Advantages

PLC Programming for Heat Stacking Machines finds utility beyond the heat stacking industry, powering applications in manufacturing, assembly lines, and quality control. Its primary competitive advantages include high accuracy, seamless integration across renowned PLC brands, and customizable on-site support. Sectors like automotive, packaging, and electronics benefit from its versatility, making it the optimal automation solution for dealers, exporters, retailers, and service providers seeking reliable and scalable control systems.

Certifications, Export Markets, and Swift Transportation

Our PLC Programming for Heat Stacking Machine carries CE certification, signifying global compliance and high valuation for international customers. With robust export markets throughout Asia, Africa, the Middle East, and Europe, every system is securely shipped and arrives promptly. Our dedicated logistics ensure careful transportation, with typical delivery times tailored to customer requirements, upholding our commitment to reliable service and efficient fulfillment worldwide.

Broad Applications and Competitive Advantages

PLC Programming for Heat Stacking Machines finds utility beyond the heat stacking industry, powering applications in manufacturing, assembly lines, and quality control. Its primary competitive advantages include high accuracy, seamless integration across renowned PLC brands, and customizable on-site support. Sectors like automotive, packaging, and electronics benefit from its versatility, making it the optimal automation solution for dealers, exporters, retailers, and service providers seeking reliable and scalable control systems.

Certifications, Export Markets, and Swift Transportation

Our PLC Programming for Heat Stacking Machine carries CE certification, signifying global compliance and high valuation for international customers. With robust export markets throughout Asia, Africa, the Middle East, and Europe, every system is securely shipped and arrives promptly. Our dedicated logistics ensure careful transportation, with typical delivery times tailored to customer requirements, upholding our commitment to reliable service and efficient fulfillment worldwide.

FAQs of PLC Programming For Heat Stacking Machine:

Q: How does PLC Programming for Heat Stacking Machines ensure precise temperature control?

A: Our solution achieves precise temperature control accuracy within 1C by utilizing advanced algorithms and high-resolution sensors, ensuring each process maintains strict quality standards.Q: What PLC brands are supported by the programming service?

A: This programming solution supports Siemens, Allen-Bradley, Mitsubishi, and Omron PLC brands, facilitating easy integration for various machine configurations.Q: Where can this PLC Programming be utilized besides heat stacking machines?

A: Beyond heat stacking, the programming finds applications in manufacturing lines, quality assurance systems, and automated packaging, supporting a broad spectrum of automation needs.Q: What is the process for customization or on-site support?

A: Simply contact our expert team with your unique requirements. We provide tailored programming services and on-site technical support to ensure optimal integration and performance.Q: When can I expect delivery after placing an order?

A: After order confirmation, units are typically shipped within the agreed timelinedelivery times vary depending on the destination and transportation method, ensuring prompt arrival.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Projects & Services' category

|

ECOSYS EFFICIENCIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free