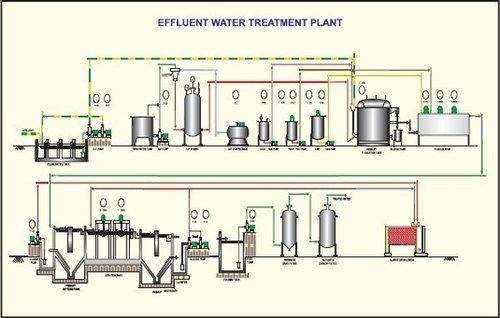

PLC Programming For Effluent Treatment Plant

Product Details:

X

PLC Programming For Effluent Treatment Plant Price And Quantity

- 1 Unit

- INR

PLC Programming For Effluent Treatment Plant Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 50 Unit Per Month

- 2-6 Week

- All India

Product Description

ECOSYS EFFICIENCIES PVT. LTD. Our company deal with Work-related Industrial Automation (PLC Programming, HMI Designing, Panel Design, SCADA, and many more). Our team has also enough experience in effluent treatment automation.

Comprehensive Automation

Implementing this PLC system streamlines effluent treatment processes, ensuring accurate control and real-time monitoring of key parameters through digital and analog inputs and outputs. The integration with HMI and data logging enhances operational visibility and decision-making.

Flexible Communication Interfaces

With Ethernet, RS232, and RS485 connectivity, the PLC can connect seamlessly to centralized networks and third-party devices. This ensures reliable data transfer for remote monitoring and integration with SCADA/DCS for enhanced process oversight.

Ease of Expansion and Integration

Designed to support future scalability, this PLC automation system allows for easy addition of equipment and supports interoperability with industry-standard systems. Its compatibility makes it a solid choice for evolving plant requirements.

FAQs of PLC Programming For Effluent Treatment Plant:

Q: How is PLC programming utilized in effluent treatment plant automation?

A: PLC programming automates the monitoring, control, and management of processes such as dosing, filtration, and discharge within effluent treatment plants. Utilizing Ladder Logic and Functional Block Diagram languages, operators can efficiently control equipment based on real-time data.Q: What communication interfaces are supported for this PLC system?

A: This PLC system offers Ethernet, RS232, and RS485 communication interfaces, enabling reliable data exchange, remote access, and integration with SCADA or DCS platforms for centralized control and monitoring.Q: When is remote monitoring beneficial in effluent treatment operations?

A: Remote monitoring is useful whenever continuous oversight and offsite management are required, such as during maintenance checks, troubleshooting, or in large facilities where operators need to access multiple plant locations from a central hub.Q: Where is the PLC unit typically installed in effluent treatment plants?

A: The PLC is panel mounted within the plants control room or near the main operational area, ensuring secure housing and easy accessibility for operators and technicians during installation, maintenance, and daily operations.Q: What is the process of integrating HMI and SCADA systems with this PLC?

A: Integration involves connecting the PLC to HMI touchscreens and SCADA/DCS systems via supported communication protocols. This allows users to visualize processes, issue commands, log data, and manage alarms efficiently from a centralized interface.Q: How does configurable alarm management benefit plant operators?

A: Configurable alarm management helps operators respond promptly to process deviations or equipment malfunctions. Alarms can be tailored to specific thresholds, improving safety, reducing downtime, and ensuring compliance with environmental standards.Q: What advantages does scalability offer in this PLC system?

A: Scalability enables users to expand the automation by adding new sensors, control units, or equipment as the plant evolves. This future-proof design lowers long-term costs and adapts easily to growing or changing operational requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Projects & Services' category

|

ECOSYS EFFICIENCIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free